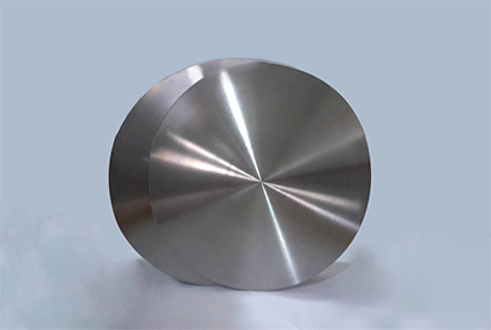

First, the basic concept of copper-nickel alloy target

Copper-nickel alloy target is a kind of widely used material, it is composed of copper and nickel and other metallic elements. Its advantages are that it has high thermal conductivity, good corrosion resistance, good electrical conductivity and plasticity and other physical characteristics. This makes it widely used in electronics, optics, aerospace and other fields.

Second, the application field of copper-nickel alloy target

1. Electronics

Copper-nickel alloy targets are widely used in the field of electronics, mainly for the production of capacitors, conductive wires, printed circuit boards and so on. The conductive wire made of Cu-Ni alloy target has good conductivity and corrosion resistance and is widely used in the electronics industry.

2. Optical field

The application of Cu-Ni alloy target in the field of optics is mainly to make lenses and optical devices. Materials made of copper-nickel alloy targets have excellent thermal and heat conductivity and perform well in high temperature environments, so they can be used to make optical devices in high temperature environments.

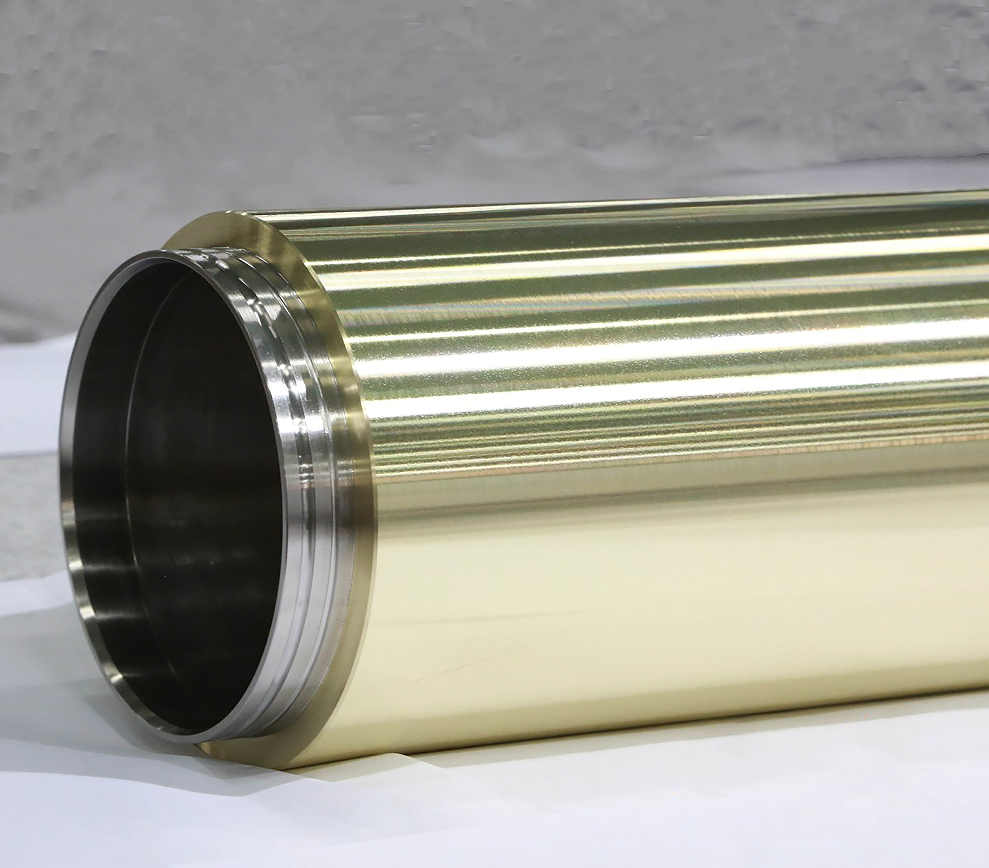

3. Aerospace

Cu-Ni alloy target is widely used in aerospace field. Materials made of copper-nickel alloy targets have physical properties such as light weight, high strength and high corrosion resistance, and can be used to make various parts and components, such as engine blades and aircraft housings.

Third, the advantages of copper-nickel alloy target

1. High thermal conductivity: Copper-nickel alloy target has a high thermal conductivity, which can make the material show more stable performance at high temperatures.

2. Good corrosion resistance: copper-nickel alloy target has good corrosion resistance, which can make the material used in harsh environments for a long time.

3. Good electrical conductivity and plasticity: copper-nickel alloy target has good electrical conductivity and plasticity, making it widely used in the field of electronics.

Fourth, Preparation method of copper-nickel alloy target

1. Vacuum arc melting method: The use of vacuum arc furnace to melt metal elements such as copper and nickel, and then solidify on the target base to become a copper-nickel alloy target.

2. Plasma spraying method: Metal elements such as copper and nickel are sprayed on the target base through plasma spraying technology, and then copper-nickel alloy target is formed.

3 Optical Industry: In the optical industry, titanium targets are used to manufacture thin films with properties such as anti-reflection, wear consumption and oxidation protection. Some specific applications include glasses coatings, camera lens elements, telescopes, microscopes and other precision instruments.

4 Storage device: In data storage devices, such as hard disks, the magnetic row layer of hard disks usually uses a thin titanium film, which has good thermal stability and wear resistance.

5 Medical device industry: In the dental field, PVD technology can be used to deposit titanium films on dental implants to enhance the bonding force with bone and improve biocompatibility.

Scan and pay attention to the public number